Hyundai: Revolutionizing Electric Vehicles with In-House Battery Technology

Editor’s Note: Hyundai's announcement regarding its in-house development of electric vehicle (EV) batteries has been released today, marking a significant step in the automotive industry's race towards sustainable transportation.

Why This Matters: Hyundai's Battery Breakthrough and the Future of EVs

Hyundai's decision to develop its own EV batteries is a game-changer for several reasons. The automotive industry currently faces significant challenges related to battery supply chain disruptions, rising costs, and the environmental impact of battery production. By bringing battery production in-house, Hyundai aims to address these challenges head-on, securing its supply, controlling costs, and potentially innovating battery technology at a faster pace. This move will not only benefit Hyundai but also influence the broader EV landscape, potentially accelerating the global transition to electric mobility. This article will delve into the key aspects of Hyundai's announcement and analyze its potential impact on the market. We will explore the implications for battery technology, supply chain management, and the overall competitiveness of Hyundai in the burgeoning EV sector.

Key Takeaways:

| Aspect | Description |

|---|---|

| Increased Control | Hyundai gains greater control over battery production and supply chains. |

| Cost Reduction Potential | In-house production can lead to lower battery costs, making EVs more affordable. |

| Technological Innovation | Potential for faster development and implementation of advanced battery tech. |

| Enhanced Sustainability | Opportunities to improve the environmental footprint of battery production. |

| Competitive Advantage | Stronger market positioning and reduced dependence on external suppliers. |

Hyundai: Eigenentwicklung von E-Auto-Batterien

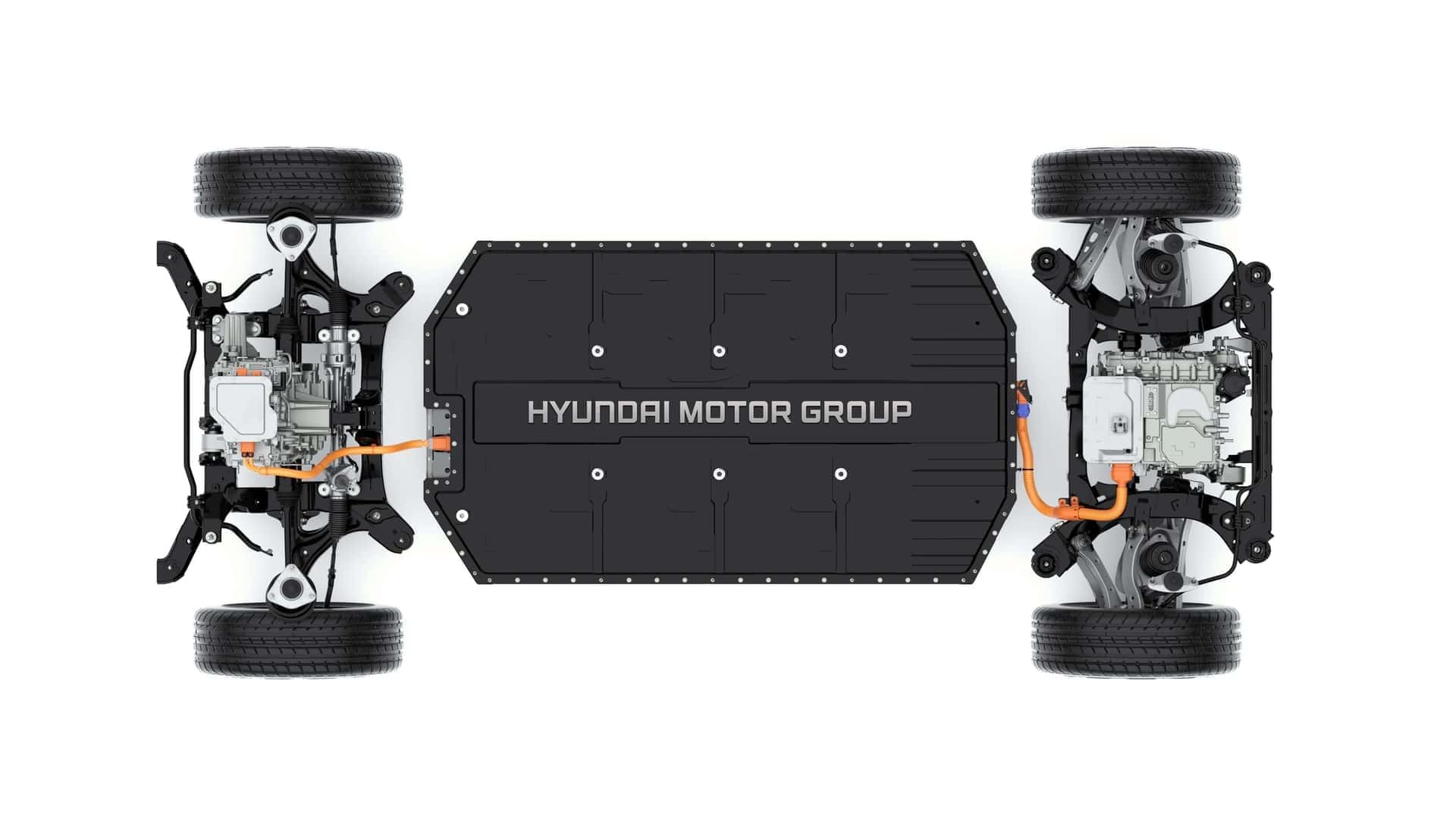

Hyundai's in-house development of EV batteries signifies a bold strategic move, positioning the company as a leader in vertical integration within the electric vehicle sector. This approach allows Hyundai to exert greater control over the entire production process, from raw material sourcing to final battery assembly. This vertical integration strategy is crucial for mitigating risks associated with supply chain disruptions – a major challenge currently facing the EV industry. The move also promises cost advantages, potentially making electric vehicles more accessible to a wider range of consumers.

Key Aspects of Hyundai's Battery Strategy

- Technological Advancements: Hyundai's investment in R&D is focused on developing next-generation battery technologies, including higher energy density batteries, faster charging capabilities, and improved battery lifespan. This commitment to innovation positions Hyundai at the forefront of EV battery technology development.

- Sustainable Production: Hyundai is committed to environmentally responsible battery production, incorporating sustainable materials and minimizing the carbon footprint of the manufacturing process. This commitment aligns with growing consumer demand for eco-friendly vehicles and manufacturing practices.

- Global Production Network: Hyundai plans to establish a global production network for its EV batteries, ensuring efficient distribution and meeting the growing demand for electric vehicles worldwide. This strategic approach solidifies Hyundai's global presence in the EV market.

Detailed Analysis: Securing the Supply Chain

The current reliance on external battery suppliers leaves automakers vulnerable to fluctuating prices, supply chain bottlenecks, and geopolitical uncertainties. Hyundai’s move to in-house production directly addresses these vulnerabilities, offering greater stability and predictability in its EV manufacturing processes. This increased control allows for better inventory management, reduced production downtime, and a more robust response to changing market demands. The ability to control the entire supply chain, from raw materials to finished products, is a significant competitive advantage.

Innovation in Battery Technology: Solid-State Batteries and Beyond

Introduction: Hyundai's commitment to innovation extends beyond simply controlling the supply chain. The company is actively investing in research and development of cutting-edge battery technologies, including solid-state batteries, which offer significant advantages over current lithium-ion technology, such as higher energy density and improved safety.

Facets:

- Roles: Hyundai’s internal R&D teams are central to developing and implementing new battery technologies. Collaboration with external research institutions and universities also plays a crucial role.

- Examples: Hyundai's focus on solid-state batteries represents a commitment to exploring next-generation technology, promising enhanced performance and safety.

- Risks: Developing new battery technology involves inherent risks, including technical challenges, high R&D costs, and potential delays in reaching market readiness.

- Mitigations: Hyundai's significant investment in R&D and its collaboration with other research institutions helps to mitigate these risks.

- Impacts: Successful development and implementation of advanced battery technology will significantly enhance Hyundai's competitive position in the EV market.

The Road Ahead: Challenges and Opportunities

Introduction: While Hyundai's move presents significant opportunities, challenges remain. The high capital investment required for establishing battery production facilities is substantial. Maintaining a competitive edge in a rapidly evolving market will require continuous innovation and efficient production processes.

Further Analysis: The competition in the EV battery market is fierce, with established players and new entrants vying for market share. Hyundai must maintain its focus on cost-effectiveness and product quality to ensure a successful market penetration.

Closing: Hyundai's strategic move towards in-house EV battery production represents a crucial step in securing its future in the rapidly evolving electric vehicle market. The company's commitment to innovation, sustainable practices, and supply chain control positions it for significant growth and leadership in the years to come.

People Also Ask (NLP-Friendly Answers)

Q1: What is Hyundai's in-house EV battery development?

A: Hyundai's initiative involves establishing its own battery production facilities to control the entire process, from raw material sourcing to battery assembly, for its electric vehicles.

Q2: Why is this development important?

A: It secures Hyundai's battery supply, reduces costs, enables faster technological innovation, enhances sustainability, and gives them a strong competitive edge.

Q3: How can this benefit consumers?

A: It can lead to more affordable and technologically advanced electric vehicles with improved performance and longevity.

Q4: What are the challenges associated with this strategy?

A: High initial investment costs, competition from established battery manufacturers, and the need for continuous innovation are key challenges.

Q5: How will Hyundai manage the environmental impact?

A: Hyundai is committed to sustainable production methods, using eco-friendly materials and reducing the carbon footprint of battery manufacturing.

Practical Tips for Staying Ahead in the EV Revolution

Introduction: The EV market is dynamic and competitive. Staying informed about the latest developments is crucial for anyone interested in the future of sustainable transportation.

Tips:

- Follow Industry News: Stay updated on the latest news and advancements in EV battery technology and the automotive industry.

- Research Different EV Models: Compare features, specifications, and prices of various electric vehicles.

- Understand Battery Technology: Learn about the different types of EV batteries and their characteristics.

- Assess Your Charging Needs: Evaluate your daily driving habits to determine your charging needs and infrastructure requirements.

- Consider Government Incentives: Research government incentives and subsidies available for purchasing EVs.

- Explore Battery Recycling Options: Learn about responsible battery disposal and recycling programs.

- Monitor Battery Prices: Keep an eye on battery prices and their impact on EV affordability.

- Evaluate Long-Term Costs: Consider factors such as maintenance, repairs, and battery replacement costs.

Summary: These tips will help you navigate the changing landscape of the EV market and make informed decisions about electric vehicle ownership.

Transition: Hyundai's commitment to in-house battery production marks a significant milestone in the EV industry. Let's conclude with a look at the broader implications of this development.

Summary (Zusammenfassung)

Hyundai's decision to develop its own EV batteries is a strategic masterstroke that addresses key challenges in the electric vehicle sector. This move promises cost reduction, enhanced technological innovation, greater control over the supply chain, and improved sustainability. The implications extend beyond Hyundai, impacting the broader EV market and accelerating the global transition to sustainable transportation.

Closing Message (Schlussbotschaft)

Hyundai's bold move underscores the increasing importance of vertical integration in the EV industry. As we move toward a future powered by electricity, what other innovative strategies will we see from automotive manufacturers to secure their place in this rapidly evolving market? Share this article to spark the conversation!

Call to Action (CTA)

Learn more about Hyundai's electric vehicle lineup and their commitment to sustainable transportation by visiting [Link to Hyundai EV Website]. Subscribe to our newsletter for more updates on the latest advancements in the EV industry!

Hreflang Tags (Examples):

<link rel="alternate" hreflang="de" href="https://www.example.com/de/hyundai-eigenentwicklung-e-auto-batterien" />

<link rel="alternate" hreflang="en" href="https://www.example.com/en/hyundai-in-house-ev-battery-development" />

(Note: Replace bracketed information with actual links and adapt content as needed for specific SEO keyword targeting.)